This beverage manufacturer wanted to improve safety and efficiency in their brewery by upgrading six clean-in-place (CIP) swing panels in high-traffic areas. The existing swing panels utilized turnback and hose connections to service various users throughout the facility. The swing panels required operators to manually hook up the proper connection before every CIP cycle creating a potential chemical exposure and slip hazard in pedestrian walkways.

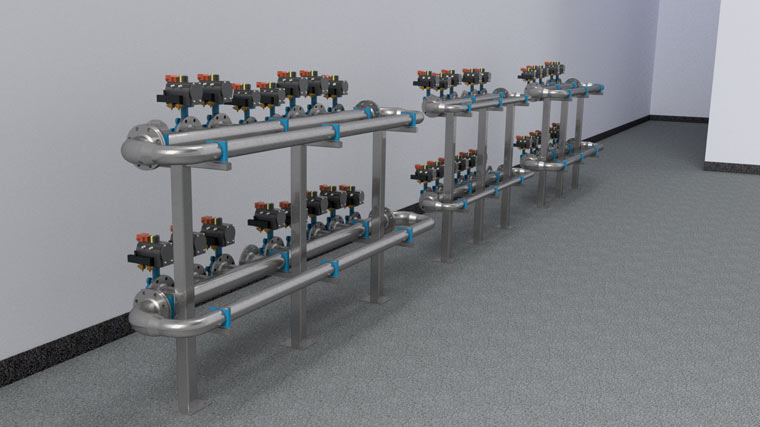

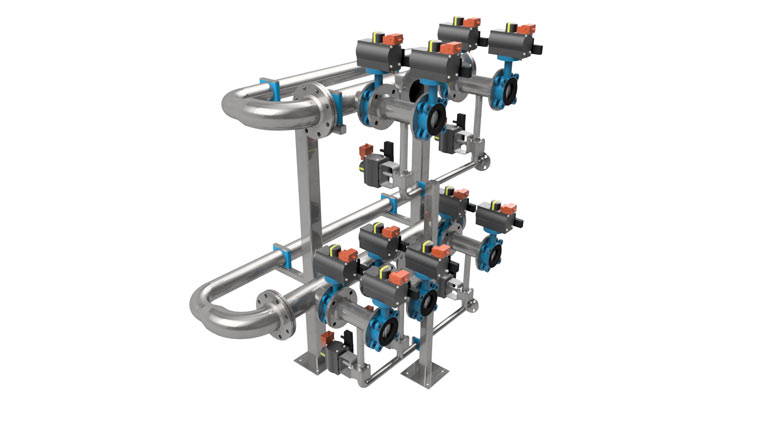

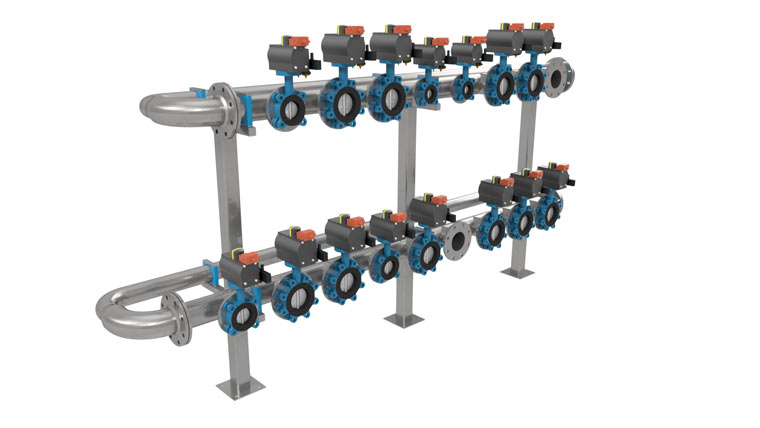

Mead & Hunt designed and fabricated six valve manifolds to replace the existing swing panels that required operator intervention and posed potential unsafe working conditions. We designed an essentially drain-free system that uses a split recirculation loop to handle flushing requirements and avoid dead leg caustic flushing problems. Automated valves in the manifold eliminated the need for operators to manually change connections for each CIP cycle. The six custom valve manifolds automated a portion the brewery’s CIP distribution process improving operational efficiency and eliminating potential safety hazards.