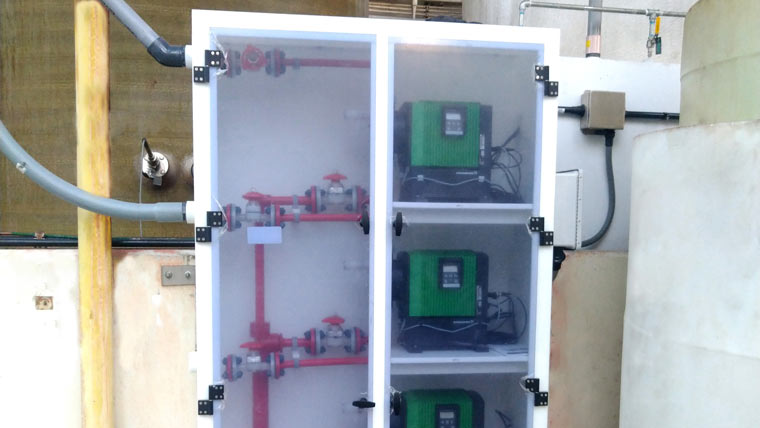

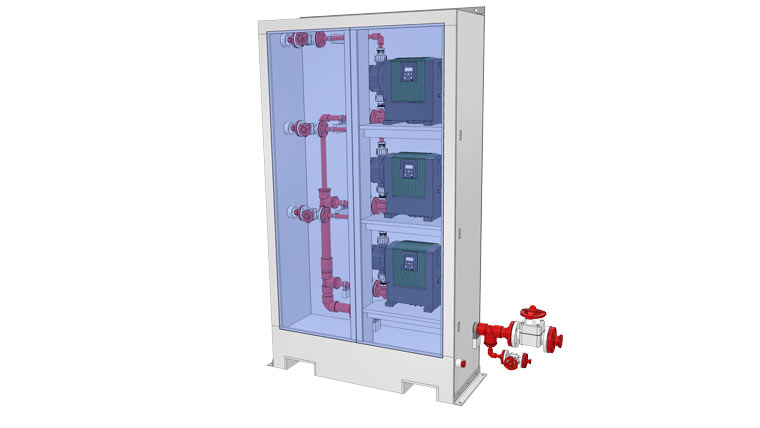

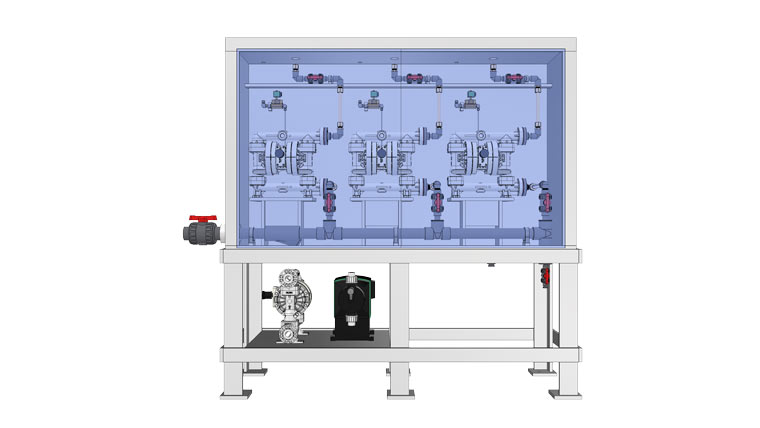

A fruit juice manufacturer needed to introduce process improvements to address their difficulty meeting wastewater pH discharge limits during high flow events. Mead & Hunt provided design, fabrication, and custom manufacturing services to create custom caustic and acid chemical feed skids. The chemical feed skids dose the process wastewater in the reaction tanks with either sodium hydroxide to increase the pH, or sulfuric acid to lower the pH, bringing the effluent wastewater within compliance of the discharge permit. Chemically resistant cabinets were designed and fabricated to fit the limited available space while providing personnel protection and ease of serviceability. These custom-fabricated caustic and sulfuric acid skids, with specially designed and built cabinet enclosures, allow the new systems to process an additional 4.55 million gal of wastewater per year while meeting pH discharge limits.

Chemical Feed Skid Fabrication

- CLIENT: Fruit Juice Manufacturer - Confidential

- LOCATION: Southern California, U.S.