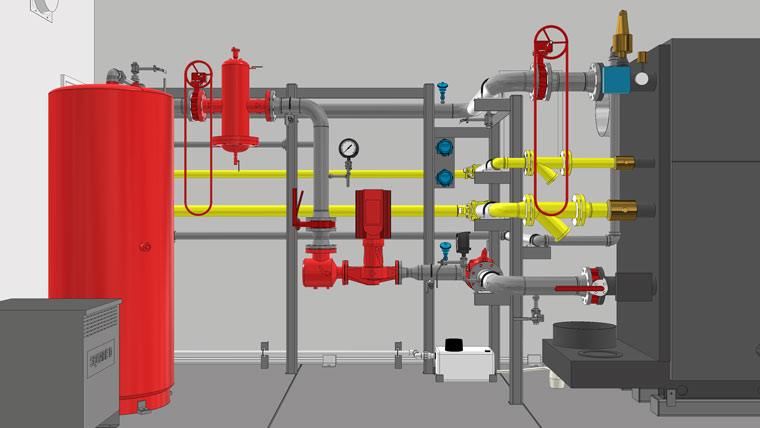

A leading renewable energy project developer that provides award-winning energy solutions needed EPC services to design and construct four dairy farm manure-to-renewable natural gas (RNG) facilities. A critical aspect of construction included the installation of a boiler heating system at each location to provide heat to the digester. Mead & Hunt provided design, fabrication, and custom manufacturing services to create four skid-mounted boiler systems. Each skid contained a 5,000 MBH gas-fired condensing boiler and a variable speed circulating pump to provide constant on-demand heat directly to the digester. Process instrumentation and a remote I/O panel were integrated, simplifying on-site installation and reducing fieldwork. A custom drop-over enclosure was designed, built, and installed prior to shipment to protect the process equipment from the elements. These custom-fabricated boiler systems supply 5,000 MBH heating capacity each, providing the reliable heat source needed to maintain digester operation.

Four Custom-Fabricated RNG Boiler Skids

- CLIENT: Renewable Energy Project Developer (Confidential)

- LOCATION: Michigan