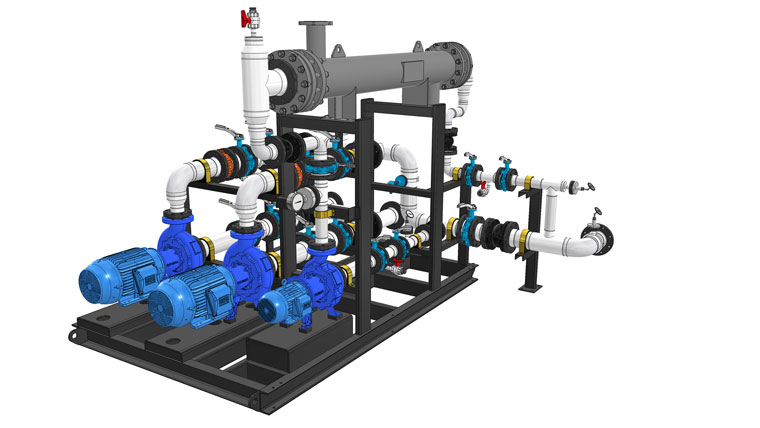

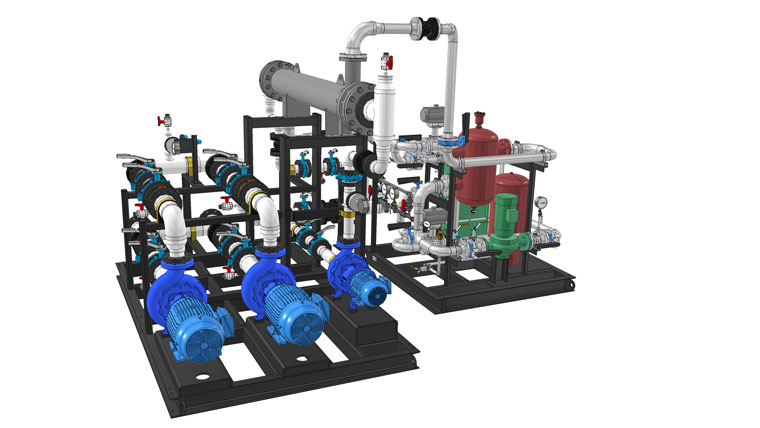

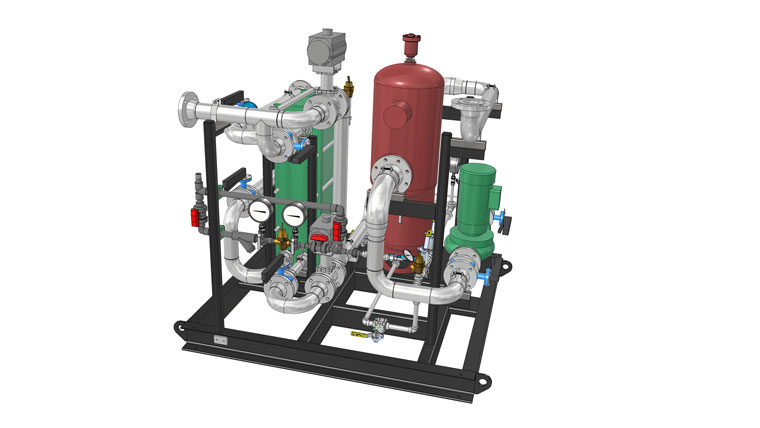

This stainless steel manufacturer was experiencing issues with the acid recirculation used in the steel pickling process at their Glasgow, Kentucky plant. The polypropylene tank and scrubber hoods were nearing the end of their useful life, and it was decided that they would need replacement. Additionally, there was no acid recirculation and mixing functionality. Our team designed a new polypropylene tank with a replaceable PVDF liner, containment pit liner, and scrubber hood system designed for a longer lifespan than traditional polypropylene-only. Our team designed and installed a duplex acid recirculation and heating skid, and secondary loop heating skid with eductor mixing to maximize pickling efficiency. Our team fabricated and tested both the acid recirculation and secondary loop heating skids concurrently with the manufacturing and installation of the new pickling tank, minimizing on-site construction and start-up time.

Pickling Tank Replacement

- CLIENT: Confidential

- LOCATION: Glasgow, KY