One of the most overlooked, yet vitally important, departments in manufacturing is the maintenance and spare parts. Skilled technicians keep assets running smoothly and continuously in a perfect world, but our world is not always perfect. Accidents happen, parts wear down from use, and mistakes are made. Emergency maintenance can become very costly, very quickly. You need to get your facility’s line or utility back up and running ASAP. After all, time is money—and with a proper maintenance program in place, you can save both.

A maintenance program is a structured schedule of equipment inspection and replacement to complete service on assets to avoid premature fatigue or failure. There are three common maintenance management approaches in the food and beverage industry: reactive maintenance (RM), preventative maintenance (PM), and predictive maintenance (PdM).

An effective maintenance program and well-equipped stock room are more important than ever in today’s manufacturing environment due to the lingering challenges of supply chain issues brought on by COVID-19. Critical parts and components that may have been readily available in the past could now be weeks out, creating extended downtime or poor production performance. How you approach your maintenance department to combat these issues is critical.

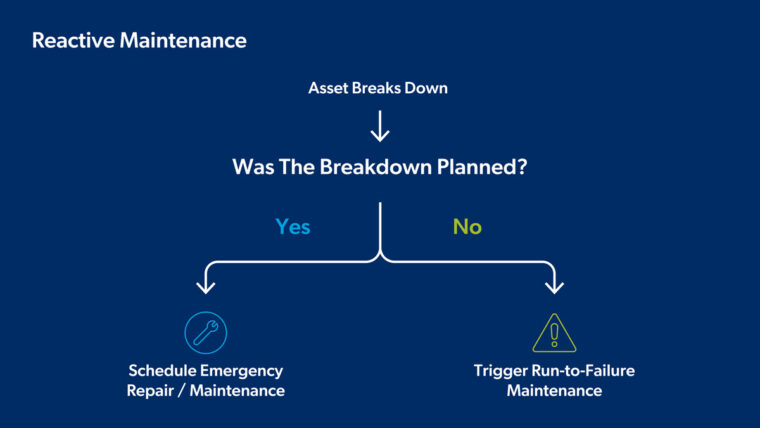

Ready, Set…STOP! – Reactive Maintenance

The RM maintenance management style is commonly called run-to-failure (RTF). You wait for a breakdown to happen and then jump into action. Although this is the most common maintenance strategy, it requires keen skills and a lean group of people to respond quickly, effectively, and safely. Food and beverage companies often remain reactive because of the historical tradition of bottom-line economics. However, the constantly changing landscape of our industry continues to push the required speed at which mechanical miracles must be achieved.

The amount of downtime incurred is directly proportional to the amount of planning and organization you put into your maintenance program. Reactive maintenance leads to the longest unplanned downtime.

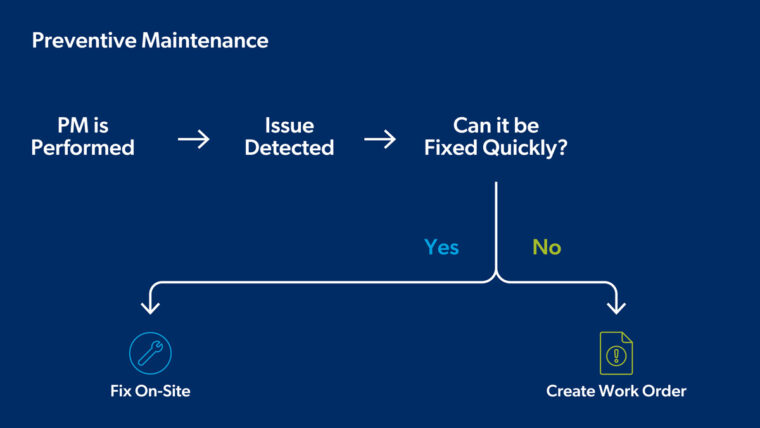

The Power of Prevention – Preventative Maintenance

You can reduce failures and downtime simply by doing checkups on your equipment, much like we take our vehicles in for oil changes. This is what preventative maintenance achieves: regular upkeep of assets instead of waiting for them to fail. The benefits of preventative maintenance are fewer downtimes for repairs, lower total cost of parts stored, and a system that can be adopted by your existing departments. Investing in your team to gain training and certifications (ex: MRO, CMT, or SMM® RMIC® ) will lead to a team who understands their system and wants to improve it. Additionally, putting eyes on your assets regularly will allow you to catch premature equipment failures before unexpected downtime occurs. To be ahead of the curve, you should improve the system with higher reliability and easier interface. Verify your current maintenance tracking system (MTS) and see if there is a better way to improve.

Another lingering impact from COVID includes people leaving the workforce. Most companies are still working to recruit maintenance technicians. As a result, manufacturers lean on suppliers and their expertise to get ahead of potential downtime situations. However, a preventative approach is more empowering. This includes keeping inventory, dedicated and regularly reviewed stock, and consistent communication to confirm parts are either in stock or on order.

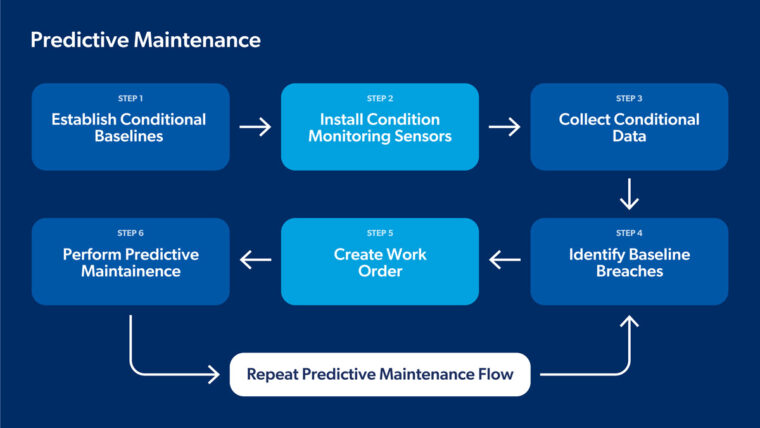

Foreseeing Failures – Predictive Maintenance

If you have a preventative maintenance program in place and your operations have improved, you can take your management one step further to become predictive.

Say a team member has kept track of a certain bearing that breaks down every year. You now have data to justify replacing the bearing every 9-12 months. The bearing likely has another month or two of life left when you replace it, but is it worth the risk of potential downtime? Don’t let a $300 part cost you hundreds of thousands of dollars per hour in lost production. Predicting the lifespan for critical spares allows consistent running with less unplanned downtime. Modern technologies can help alert you when an asset is not functioning properly. While this management style requires added upfront capital and resources, your operational and maintenance costs will be greatly reduced.

Short-term Pains for Long-term Gains

When success is measured by production volumes and runtimes, added onus is placed on our team’s ability to quickly respond to equipment failures. Regardless of how your maintenance and parts management currently operates, you can always improve your system by applying preventative and predictive strategies and principles.

Why wait and risk tomorrow’s productivity? Start implementing a higher standard of management today. The minor pains that may be realized now are only temporary. The benefits of an effective maintenance management program will improve not only your maintenance department but the efficiency of the entire facility.