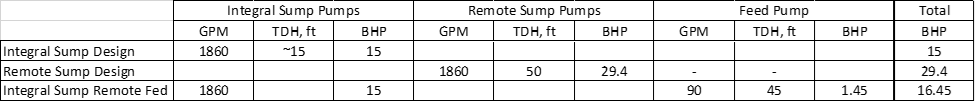

When it comes to the industrial refrigeration industry, there are generally two methods evaporative condensers use for water circulation: the remote sump design and the integral sump design. The energy cost between the two designs varies greatly—the remote sump design is nearly twice the operating cost of the integral sump per year. Our team often uses hybrid approach that combines the methods to give clients the best of both options. We call it “Integral Sump Remote Fed.”

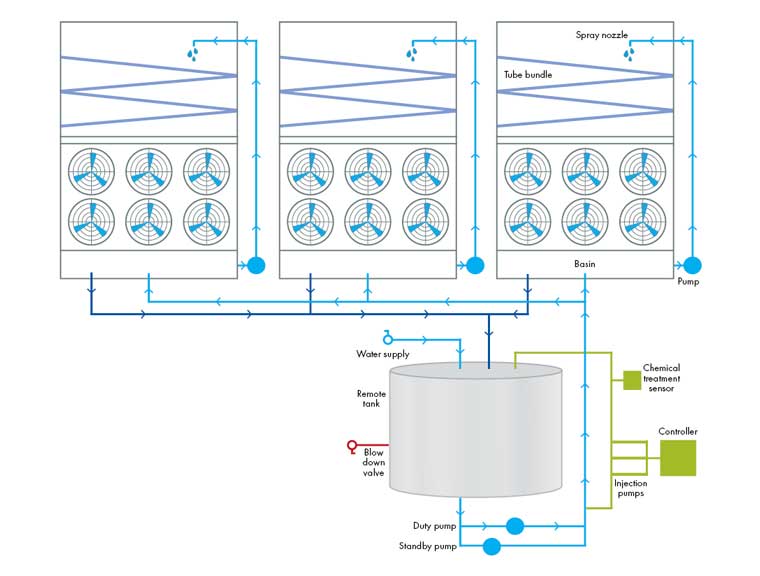

Here’s how it works:

As shown, the hybrid solution uses one chemical treatment system for multiple condensers with one water makeup valve and one blowdown valve. The chemical treatment is distributed evenly to each condenser. This design avoids water waste and significantly reduces cost when it comes to winterizing the condensers. As an added bonus, the design takes smaller piping. All of this translates into increased efficiency and cost savings for the client.

As seen in the chart, the energy cost premium of the Integral Sump Remote Fed design is nearly negligible: less than $1,000 per year over the standard integral sump design.

The Mead & Hunt team has implemented this design at several locations with happy customers. We presented the design at a client meeting recently, and multiple people took out their phones to snap a picture.

Based on this enthusiasm, we felt it was a good idea to share with others in the industry, so we recently created a white paper explaining the design in more detail. The goal here is to share new ideas, best practices and innovations with others throughout Food & Beverage world, so we can all continue to bring the most efficient, effective solutions to clients. Through this collaboration, we can elevate our industry, clients and communities.