Ammonia systems used for industrial refrigeration offer a reliable, cost-effective, energy-saving approach to refrigerant for large industrial operations. But, like most high-use equipment, refrigeration systems can suffer issues. In this blog, I’ll share how you can freeze problems in their tracks before they occur.

Problem 1: Trapped Liquid

Like all substances, liquid refrigerants expand and contract with changes in temperature. Be cautious when closing isolation valves on piping or equipment that could be mostly or completely full of liquid refrigerant, as the valve could block that path and trap the liquid. Once liquid is trapped, each degree of temperature rise can result in an additional 100-150psi of pressure. This can lead to significant damage and even bursting components.

How can you get trapped liquid in your system to go with the flow? Try these options:

- Review equipment SOP before making valve position changes

- Position check valves on the downstream, outlet side of solenoid valves

- Avoid valving off evaporative condensers in very cold weather or light plant load conditions

Problem 2: Liquid Hammer

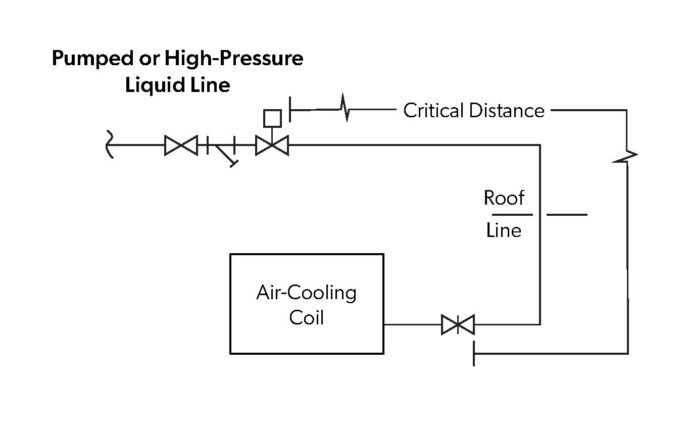

Liquid hammer is the rapid deceleration of flow in a liquid line caused by a snap-acting solenoid valve. Similar to water hammer in a water distribution system, it often causes piping movement and loud bangs or thuds. Liquid hammer can cause serious damage, leaks, shortened lifespan of your piping, and valve failures.

Here are actions you can take to prevent liquid hammer:

- Install a solenoid valve as close as possible to the metering device on a high-pressure liquid feed to a low-pressure vessel or direct expansion evaporator

- Install a throttling device directly downstream of the solenoid and at each user (assuming a solenoid is feeding multiple evaporators)

- Limit the size of liquid make-up solenoid/hand expansion combos to 1.5 inches

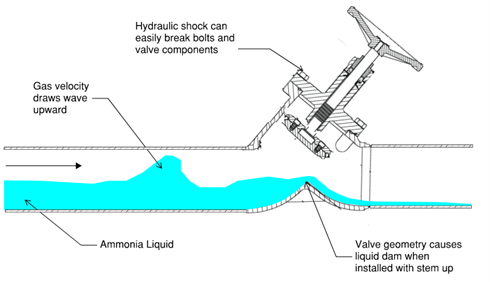

Problem 3: Vapor-Propelled Liquid

Vapor-propelled liquid is high-velocity liquid propelled by high-pressure vapor. As vapor velocity increases, like an internal tsunami it creates a wave that slams against an elbow, valve, or end of pipe causing a sudden decrease in speed. Vapor-propelled liquid can cause serious damage. Beyond the concerning loud noises, pipes and equipment could shift. Gauge needles might pin beyond their stop. Flange bolts can require repeated tightening. Down the line, this can build into a tidal wave of problems.

To prevent vapor-propelled liquid, you can:

- Install liquid drains at low points in the hot gas mains so lines stay liquid-free

- Use pressure sensors as a safeguard in addition to traditional timed sequencing for defrosts

- Avoid normally open gas-powered suction stop valves

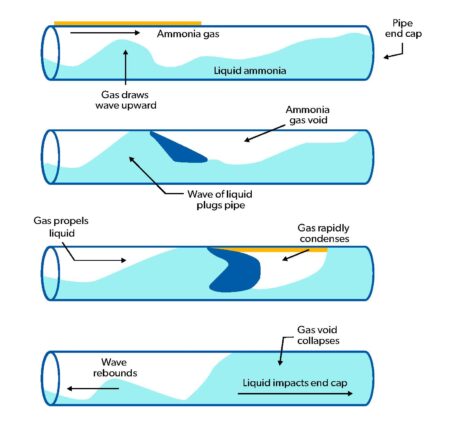

Problem 4: Condensation-Induced Shock

A perfect storm can coalesce inside your system. Condensation-induced shock occurs when warm vapor flows over a cold liquid. As the vapor velocity increases, the gas creates increasingly higher waves in the liquid. Once a wave of liquid “plugs” a pipe, it creates a gas void. As the wave travels down the pipe, the void becomes more compressed and condenses. Once the gas has condensed, the void further accelerates the wave in the pipe. Like liquid hammer and vapor propelled liquid, this can cause serious damage including gauge needles pinned beyond their stop, pipe caps blown off, and coil headers ruptured.

Here’s how to keep the calm and prevent the storm of condensation-induced shock:

- Never introduce hot gas under or into cold liquid

- Never transfer cold liquid into a higher temperature suction line

- Never connect a cold liquid transfer system outlet to the condensate return line from the condensers

Remember, the best solution is prevention

These four common problems are preventable with the suggestions listed above. However, the best preventative measure is to pay attention and learn what your system looks and sounds like when functioning normally. Often, systems run smoothly for extended periods and seem to suddenly experience problems because no one realized there was an issue brewing in the first place. If you learn your system, you will be more likely to spot these common problems and others before they cause significant issues in your plant. Finally, never ignore or assume pipe movement or loud bangs and thuds are normal; investigate right away.