While hydropower facilities may not receive as much attention as newer technologies like solar and wind, America’s hydroelectric infrastructure remains a valuable resource to power our communities. The U.S. hydroelectric fleet has faithfully served its role, helping meet our energy needs for the better part of the last century.

Beyond generating power, these facilities provide flood protection, water supply, and recreational opportunities to millions of Americans. With the right strategic approach, these facilities can be cost-effectively modernized for another century of service.

Here’s how a three-phase rehabilitation strategy is helping dam operators adapt aging infrastructure to enhance performance and safety.

The Strategic Three-Phase Approach

Phase 1: Assessments Build the Foundation for Smart Decisions

Before rehabilitation work begins, an assessment is often the first step in identifying and prioritizing rehabilitation opportunities. A FERC Comprehensive Assessment (CA) identifies potential failures and develops risk information from a safety perspective to better prioritize investments. Specialized studies like Hydrologic Hazard Analysis (HHA) provide the technical foundation for understanding loading conditions used in developing Potential Failure Modes (PFMs) during the CA process.

Real-World Impact

Mead & Hunt conducted a detailed HHA for a large reservoir used for hydropower, flood protection, and recreation in the Midwest. Our detailed HHA evaluated extreme hydrologic loading conditions across dozens of upstream reservoirs. By developing inflow-duration and stage-frequency curves, plus incorporating historical flooding data, we provided dam operators with quantitative information to assess risk and make an informed decision for dam safety rehabilitation and operational planning.

Phase 2: Interim Repairs Buy Time for Strategic Solutions

When structural concerns arise from routine monitoring or unexpected failures, interim repairs can offer immediate safety improvements while permanent solutions are being developed. These targeted improvements are applicable when operators face high demolition costs, lengthy agency approvals, or require specialized studies, such as spillway erodibility analyses or Probable Maximum Flood (PMF) studies, that could delay larger repairs.

Case Study

At a California hydropower facility originally built in the mid-twentieth century, a phased interim repair program was initiated at a combined hydropower forebay and diversion dam. Instead of rushing into expensive permanent reconstruction, our team designed a phased repair program delivered over several short construction windows to minimize impact on operations.

The repairs focused on restoring structural integrity of the joints and hydraulic performance while a long-term solution was developed in coordination with a site-specific PMF study by others. Critical interim repairs included wall stabilization, joint sealing, concrete patching, apron repairs, drain inspection and clearing, and select wall drain replacement. This risk-informed approach identified repairs while balancing the construction schedule and continuing effective water management. Operations and monitoring were adjusted to accommodate the interim conditions and justify the continued use of the spillway.

Engineer oversight, combined with quality assurance testing, assured repairs met performance standards. The interim repairs have successfully extended spillway service life by over five years, providing valuable time to develop a plan for larger upgrades while maintaining safe, reliable operation.

Phase 3: Permanent Improvements Reinforce Century-Old Solutions

Modern spillway design involves hydraulic innovation, structural resilience, and practical constructability to build facilities that meet current standards while improving overall performance.

Innovation in Action

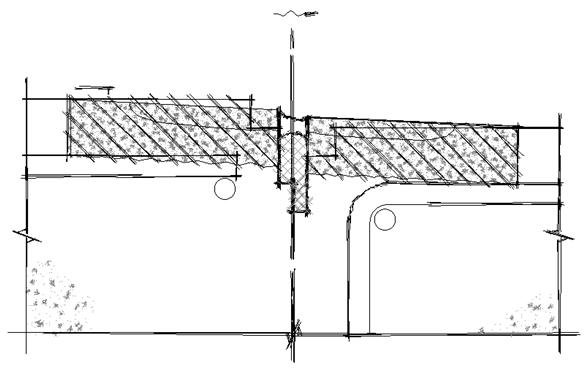

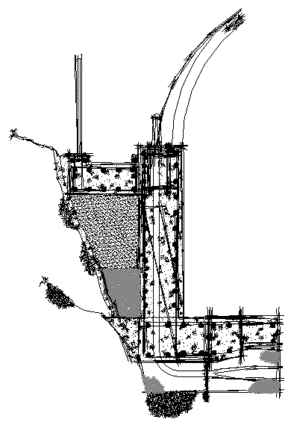

A recent in-place spillway replacement project for a nearly century-old mountain hydropower facility exemplifies this approach. Assessment had identified structural deficiencies and capacity limitations in the original spillway chute, which decreased in width and turned along its length, potentially causing water to overtop onto erodible ground during higher flows.

The solution involved a curved deflector design that directs flow upward and back toward the spillway center, more than doubling flow capacity within the existing footprint while requiring significantly less wall height than a straight extension.

The modernized design also includes:

- Hydraulically favorable joint offsets to mitigate cavitation risk

- Embedded PVC waterstops to minimize under-slab flow

- Mechanical connections protecting against hydraulic jacking

- Robust underdrain systems with accessible inspection and maintenance features

- Chute slab anchorage designed for uplift protection

Construction challenges in the steep, remote location were addressed through strategic crane pad design, widened access roads, and the use of precast concrete segments for the curved deflector. This approach streamlined installation while accommodating short construction seasons and wildfire risk.

Hydroelectric Remains Viable and Valuable

After 150 years of operation, adhering to increasingly sophisticated regulations and safety requirements, America’s hydroelectric fleet has proven its resilience and adaptability. As the real-world case studies above highlight, proactive investment in strategic rehabilitation is cost-effective and a pathway to securing another century of reliable, clean energy. With innovative engineering and a strategic three-phase approach to improving aging hydroelectric infrastructure, these facilities are positioned for long-term success.